Annmarie Bhola is the owner of Enhanced Building Solutions, LLC – EBS is committed to transforming the culture within the building industry through training and leadership.

I recently read “The Power of Habit” by Charles Duhigg and wanted to share the ALCOA Plant story: In 1987, one important change created a ripple effect that transformed an entire company, dramatically improving culture, quality, productivity, communication and profits. They found the right habit to focus on, and it changed their whole operation.

I’ve identified that habit in building engineering and operations from my many years in the industry, and I’m going to share it with you. But first, here’s what happened at the ALCOA Plant:

Before Paul O’Neill decided to take the CEO position at ALCOA, he decided to write a priority list to determine what would be necessary to help the then-struggling company. Critics told him that the union workers weren’t nimble enough and the quality of the products were poor. Despite this, O’Neill didn’t put efficiency or quality as the biggest priorities on his list.

“At a company as big and old as ALCOA you couldn’t just flip a switch and expect everyone to work harder or produce more.”

The previous CEO had tried to mandate improvements, and it resulted with 15,000 employees going on strike. Morale was so bad that employees brought in dummies, dressed them like managers, and burned them in effigy.

O’Neill had to think constructively and find a common ground where unions and executives would agree. He needed a focus that would bring people together; a priority that would provide leverage to change the way people worked and communicated. Worker’s Safety!

Focusing on safety created a ripple effect in the company. His ambitious goal of making ALCOA the Safest Company in America with zero injuries initiated quality training from the workers all the way up to the CEO.

Duhigg refers to Paul O’Neill’s aspiration as a “Keystone Habit.” According to Duhigg, Keystone Habits start a process that, over a time, transforms everything. Success doesn’t depend on getting every single thing right but instead relies on identifying a few key priorities.

“I knew I had to transform ALCOA. But you can’t order people to change. That’s not how the brain works. So I decided I was going to start by focusing on one thing. If I could start disrupting the habits around one thing, it would spread throughout the entire company.”

Where the previous CEO just medicated the issues with mandates, O’Neill’s plan went to the source of the reason for low morale and workplace injuries. He looked at why injuries happened in the first place. And to understand why injuries happened, you had to study how the manufacturing process was going wrong. To understand how things were going wrong, you had to invest in training workers about quality control and the most efficient work processes. Better processes led to safer work.

In other words, to protect workers, Alcoa needed to become the best, most streamlined aluminum company on earth.

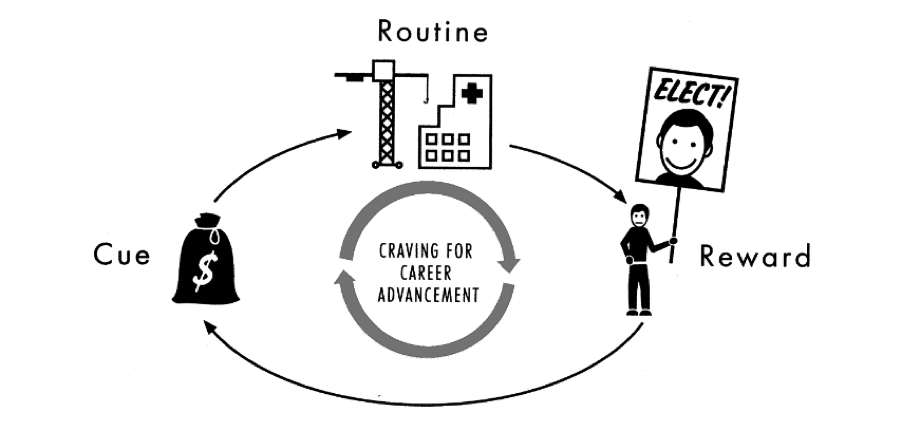

O’Neill’s safety plan, in effect, was modeled on a habit loop. He identified a simple Cue: an employee injury. He instituted an automatic Routine: Any time someone was injured, the unit president had to report it to O’Neill within twenty-four hours and present a plan for making sure the injury never happened again. And there was a Reward: The only people who got promoted were those who embraced the system…

So how do you make this kind of change in your building?

I see Preventative Maintenance as the Keystone Habit for the building industry, and rounds in buildings as the routine. Cue: Required preventative maintenance, Routine: Performing daily rounds. The Reward: An efficiently operated building. Consistent, organized, and purposeful building inspection rounds help you identify what is going on in your building, you must communicate what needs to be done, to determine how to make your building better. Training staff on their daily responsibilities vs the scheduled contracted maintenance creates a synergy within.

I tell the people I work with to use LogCheck; it creates the habit of meaningful building rounds. LogCheck is the fastest tool to implement (in less than 2 weeks, you can be up and running). It speeds up the rounds and communication process. Incorporate it with a proper training plan and it will Enhance a better culture and result in a successful organization!

…Oh and as a result, ALCOA’s sales rose from $1.5 billion in 1987 to $23 billion in 2000 when Paul O’Neill retired. It turns out that focusing on one, highly impactful habit can improve several routines — and the bottom line.

0 Comments