If you were to take your body temperature right now, it would probably read within 1 degree of 98.6°F. If not, it’s time to go to the doctor. A temperature reading outside of your body’s normal operating range is usually an indicator of some sort of other problem. The same goes for your mechanical equipment.

This idea isn’t anything groundbreaking. But while normal operating range for human body temperature is widely known and agreed upon, equipment ranges in specific installations aren’t always so clear. What’s the right hot water boiler pressure at your building? Or the ideal stack temperature?

More importantly, does everyone on your team know and agree what that normal range is? If it’s not explicitly codified and easily accessible by your whole team, you’re almost certainly going to have different ideas of what is “normal” and what isn’t.

It may seem trivial, but it’s not.

Here’s an example: If domestic hot water supply temp gets too high, burn risk increases significantly (not to mention the lawsuits that follow). On the other hand, if that temperature drops just a degree or two below the ideal operating range, you create a perfect environment for legionella to grow. So it’s absolutely vital that you maintain a very specific temperature range at the faucet.

So how can you keep everything in check? Easy: first, determine and agree upon your ideal operating range. It can be based on equipment specs, your own historical data, or researched statistics, but your team must understand and agree on that range. Then, prominently display minimum and maximum ideal readings so that every time you or anyone on your team takes a reading as part of your routine inspection rounds, you’ll have the exact data right in front of you.

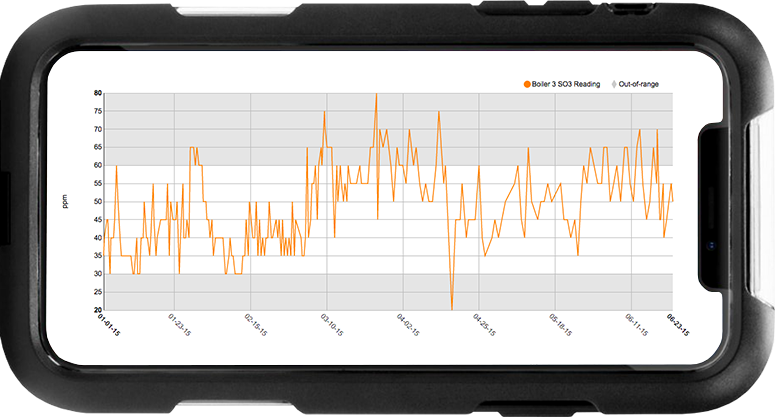

In LogCheck, we’ve built this right into our app. You can set a min or a max for any numerical log, and if you enter a reading outside of that range, an alert warns the operator in the field and flags the reading on the web dashboard, so any abnormal reading gets tended to quickly.

Even if you don’t use LogCheck, be sure to document this somehow. Include it in your log sheet template. Tape it to your gauges. Attach a placard to your equipment. It doesn’t matter how, but make sure you do something.

…Or better yet, click the button below and leave your information and we’ll set you up with a free trial of LogCheck so you can try it for yourself.

Thanks for reading, everybody. If you liked this post, please share it on Facebook. And if you find my Tips Of The Week useful, be sure to sign up for our weekly newsletter, so you never miss a post.

Thanks again, and have a great week.

0 Comments